Al Bunnia

Cold Asphalt (CAS-WP25)

Specialists in the Manufacture of Cold Asphalt

for Maintenance Purposes Only

Product identifier: COLD ASPHALT PLUS

Chemical Name: Mixture

Trade Name(s): CAS–WP25

Packing: 25 KG / Bag

Expiry Storage: 18 Month

The area is covered by one cold asphalt bag of 25 kg Approximately:

25 KG / Bag covers an area of around (45 CM length × 45 CM widths × 5 CM depth).

Company Identification:

Al Bunnia Contracting and Trading and Production of Raw Materials LLC.

Headquarters: Sultanate of Oman – Muscat- Al Jaffnain.

Commercial Register: 1393691

Phone: 0096896587970

Website: Albenya.com

Email: info@albenya.com

Relevant identified uses of the substance or mixture and uses advised against

Identified Use(s) Road Maintenance

Uses Advised Against None

For more information, choose a means of communication.

Contact us via WhatsApp

Chat on WhatsAppContact us via messages

Send your inquiriesOur Cold Asphalt Features

Easy To Use

Environment Friendly

25 KG Bags

Need Simple Equipment

Easy To Transfer

Doesn’t disrupt traffic

armed with fiberglass

Holds together after tamping

Any Weather

Easy To Trade

HOW TO USE (CAS-WP25)

Step 1

Clean the hole well of old debris

Step 2

Empty the bag into the hole

Step 3

Tamp the hole well and it is preferable to use a roll compactor

How To Storage

One Pallet Per Stack

It is forbidden to stack the pallet on top, meaning a maximum of one pallet per stack.

Closed Warehouse

Store in a closed warehouse and do not expose the stock to the sun to avoid damage to the product.

Wooden Pallet

It is stored on a wooden pallet of 40 bags per pallet.

Packing

The packaging is carried out in 25 kg bags made of polyethylene.

INFORMATION ON INGREDIENTS

| Composition/information on ingredients | % wt | CAS No |

|---|---|---|

| Aggregate (crushed stone, sand, gravel) | > 85 | Various |

| Silica sand Or Quartz sand | < 5% | 14707-60-7 / 14808-60-7 |

| Petroleum asphalt / bitumen | < 5% | 8052-42-4 |

| Additives + Fiberglass + Filer | < 5% | Various |

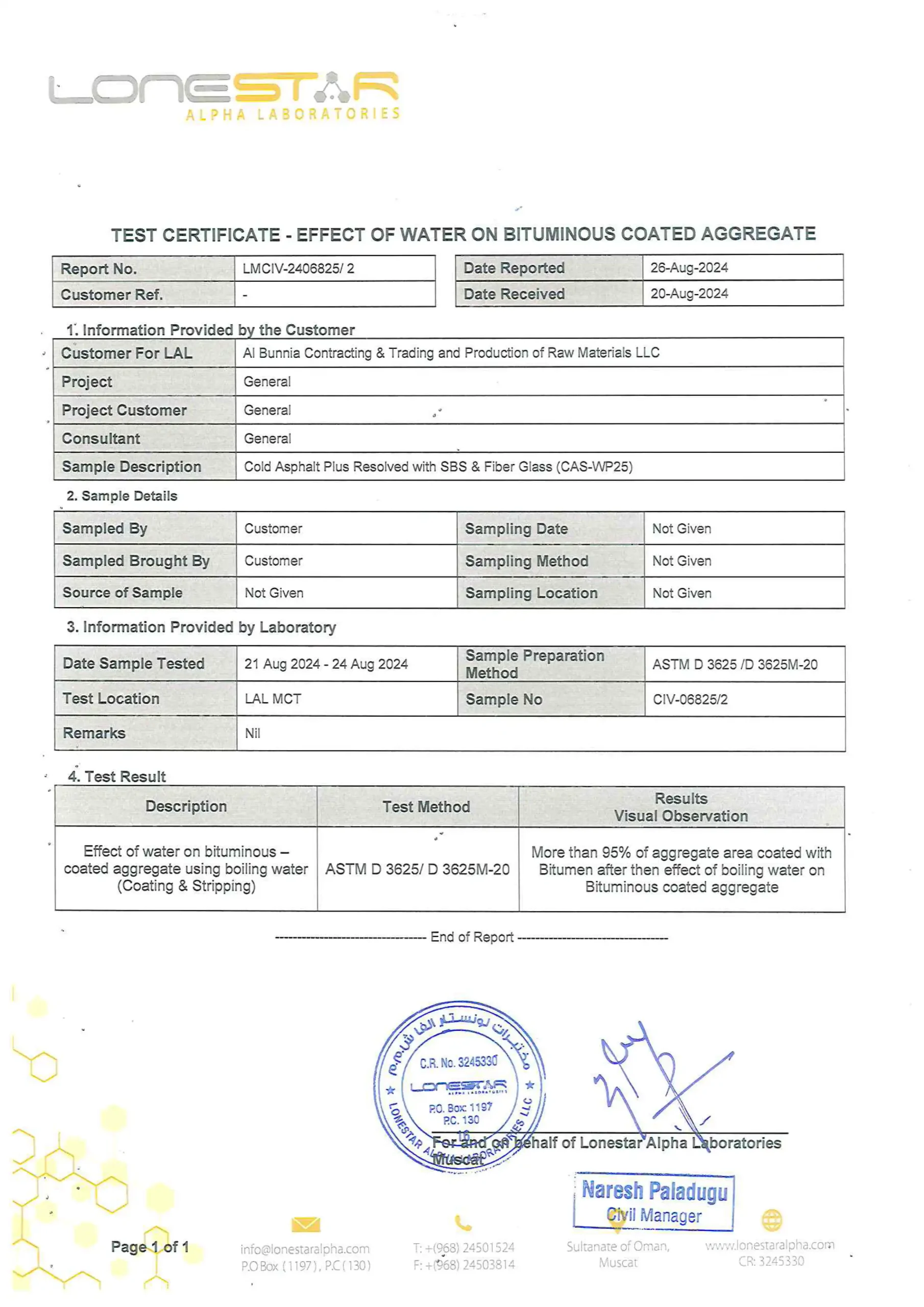

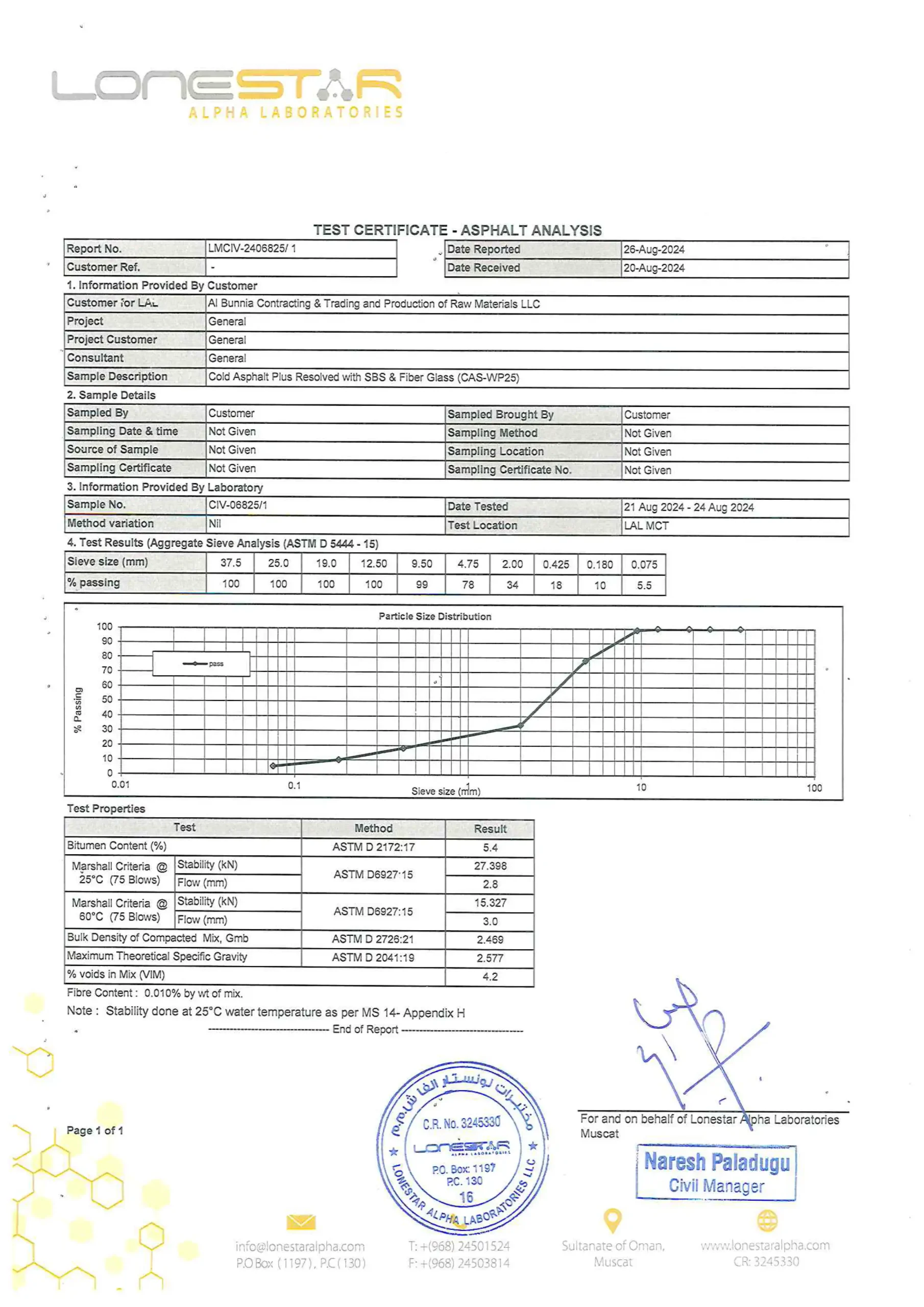

LAB RESULTS

Ref | Method | Result Range | |

Binder Content (%) | ASTM D 2172: 17 | 5.0-5.4 | |

Marshall Criteria @ | Stability (N) Flow (MM) | ASTM D 1559: 89 | 27398 2.8 |

Marshall Criteria @ | Stability (N) Flow (MM) | ASTM D 1559: 89 | 15.327 3 |

Bulk Density | ASTM D 1559: 89 | 2.469 | |

% voids in Mix (VIM) | 4.2 |

HAZARDS IDENTIFICATION

OSHA HCS (29 CFR 1910.1200) / GHS Classification Eye Irrit. 2; Skin Sens. 1b

Signal Word(s) WARNING

Wear protective gloves /eye protection. Wash hands and exposed skin after use.

Classification of the substance or mixture

Hazard Symbol

It May cause serious eye irritation. May cause an allergic skin reaction. Precautionary Statement(s)

FIRST AID MEASURES

Description of first aid measures

Inhalation Not normally required

Move person to fresh air

Apply artificial respiration if necessary

If symptoms persist, obtain medical attention

Skin Contact Gently wash with plenty of soap and water

If irritation (redness, rash, blistering) develops, get medical attention

Eye Contact Flush eyes with water for at least 15 minutes while holding eyelids open

Remove contact lenses, if present and easy to do

Continue rinsing. If irritation develops and persists, get medical attention

Ingestion Not normally required. Do not induce vomiting

Do not give anything by mouth to an unconscious person.

Get medical advice/attention if you feel unwell.

Indication of any immediate medical attention and special treatment needed.

The most important symptoms and effects, both acute and delayed may cause an allergic skin reaction.

OTHER INFORMATION

Description of first aid measures

Al Bunnia reserves the right to change or modify the data without prior notice.

All reasonable care has been taken in compiling the data that to the best of our knowledge is accurate and true.

All recommendations are made in good faith.

No responsibility can be accepted by us and no warranty is implied with regards to any of the recommendations made in the data sheets, since the condition of actual use and the labor involved are beyond our control.

The products are warranted against manufacturing defects only and sold subject to Al Bunnia Company’s standard terms and conditions of sale.